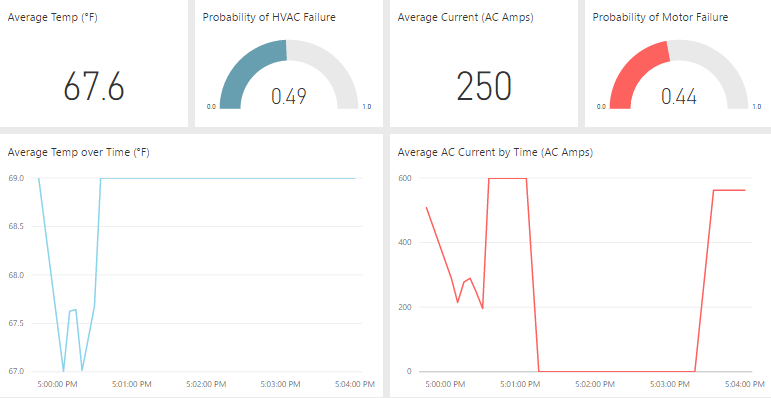

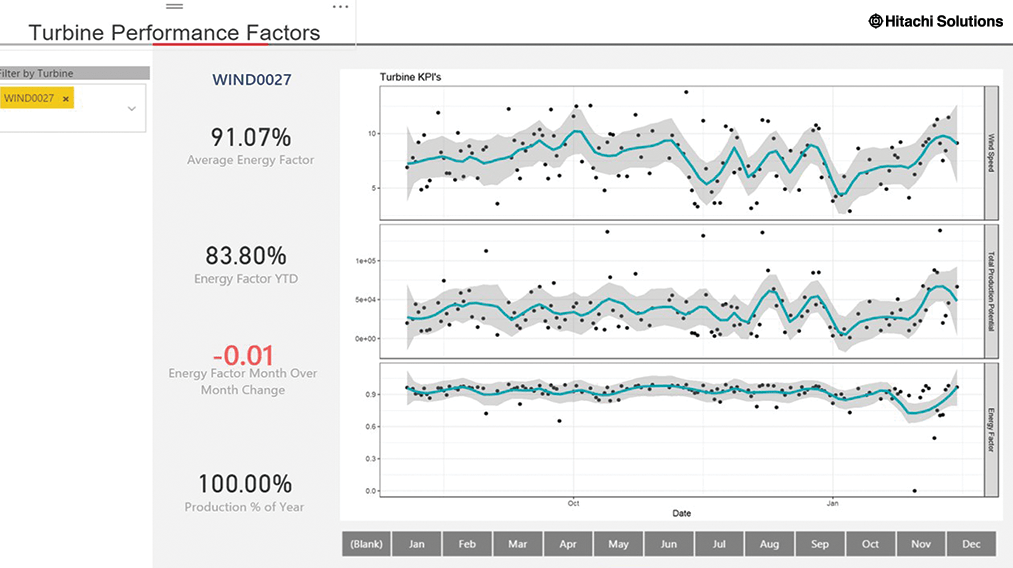

Predictive maintenance

Pinpoints equipment and component issues and failures before they occur, leading to reduced maintenance costs and unplanned equipment downtime, and extending useful life of capital equipment.

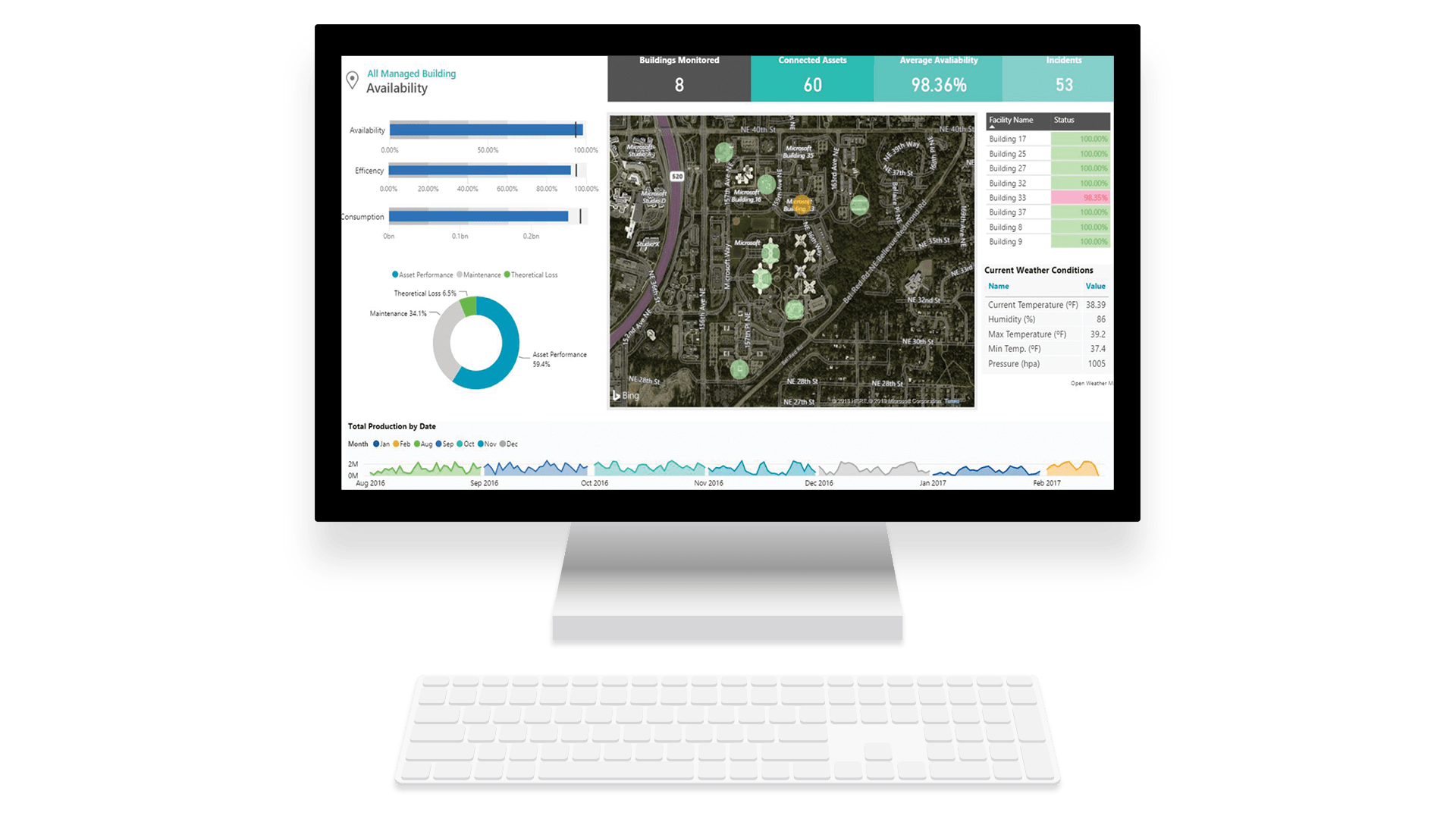

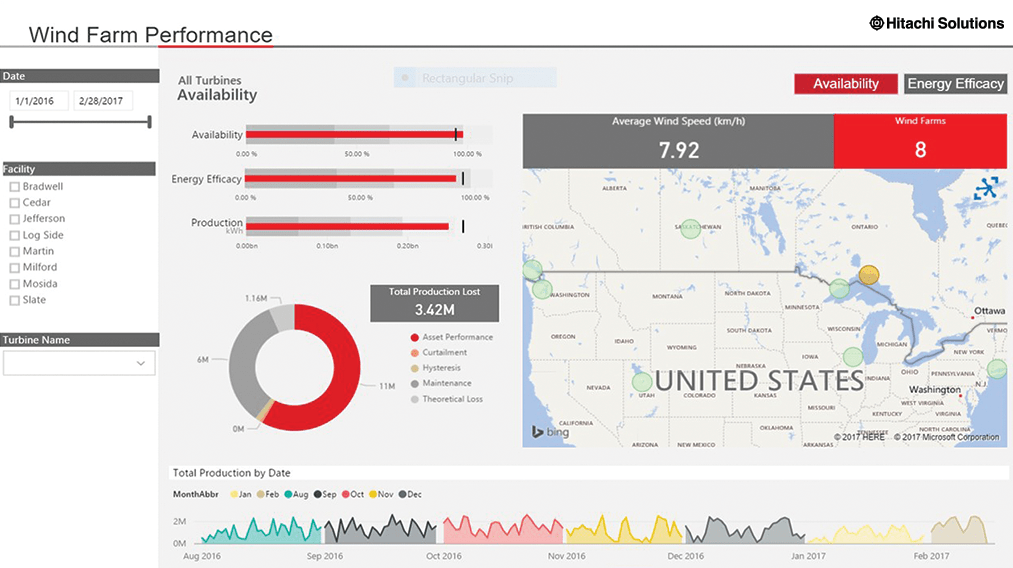

Equipment monitoring and telemetry

Collects data at remote or inaccessible points and transmits for monitoring to increase the understanding of what’s occurring at the edge and transition from reactive to proactive maintenance.

Field service automation and repair

Monitors and assesses machine “health,” making it possible to know exactly what needs to be repaired, along with the necessary parts and technical skill levels. Automation also includes the ability to track parts, technicians, equipment warranties, and automate the flow of work orders, invoices, inventory, time/expenses, and more.