Compete and Win With an Intelligent Supply Chain

Create operational agility with analytics, automation, and new delivery models.

Download the WhitepaperDigital transformation continues to impact nearly every branch of every industry – from large-scale production and transportation down to individual customer service and eCommerce. Customer Packaged Goods (CPG), retail, and manufacturing have seen some of the largest transformations through advances in digital technology. There is a multitude of process areas we can examine to learn how to best reap the benefits of digital transformation. For now, let’s focus on one – supply chain management.

Intelligent supply chain management calls for the implementation and leveraging of modern technologies to optimize various facets of the supply chain. With an intelligent supply chain, companies leverage modern technologies to collect data and develop insights to better optimize their supply chain. This can save on costs, increase profitability, increase their speed to customers, and get ahead of their competition.

What Does Intelligent Supply Chain Management Look Like?

Intelligent supply chain management is possible when businesses take full advantage of the latest retail digital transformation technologies – artificial intelligence (AI), machine learning (ML), predictive analytics, unified commerce, and big data.

Artificial intelligence, which encompasses machine learning and predictive analytics, is helping to power supply chain business intelligence. These technology solutions utilize big data, logistics patterns, and business trends to inform and optimize the entire digital supply chain. While aspects of the supply chain historically were manual and imperfect, intelligent supply chain management is greatly improving accuracy and visibility.

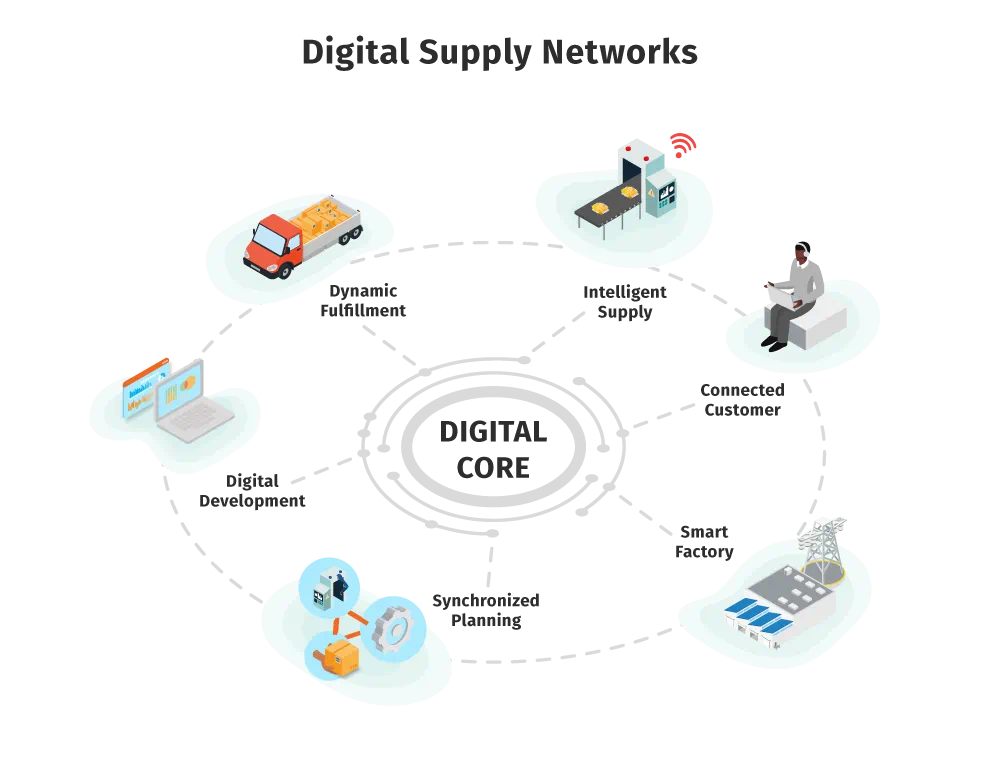

So, what does this all mean? Intelligent supply chain management means that the supply chain is no longer an independent entity of retail or manufacturing companies. Today, all areas of operation — your supply chain included — should be integrated and optimized using connected networks and troves of data to vastly improve forecasting, decision-making, cost control, and overall efficiency.

How to Move to Intelligent Supply Chain Management

- Implement the Internet of Things-linked systems and devices. Internet of things (IoT)-based systems are essential to managing complex, omnichannel supply chains due to the worldwide nature of potential customers and shipments. These devices improve supply chain visibility by giving AI, machine learning, and predictive analytics the data they need to generate actionable insights.

Goods can be equipped with monitoring devices that allow CPG companies and retailers to track products throughout the supply chain journey. From manufacturing, storage, transportation, and final destination, the data generated from goods/containers will provide insight into purchasing and selling cycles, how frequently inventory should be restocked, and how much should be kept in stock. - Use big data and algorithms to identify inefficiencies. With IoT-enabled devices throughout the intelligent supply chain, companies can now collect thousands of data points that can be utilized to improve each step of the supply chain process. Using AI, data science, and predictive analytics, both retailers and manufacturers can quickly make improvements and identify inefficiencies that need to be addressed.

Predictive analytics and big data will empower companies with insights to reduce downtime, optimize workflows, and keep operations running at their maximum efficiency. This information can also guide new optimization strategies that extend beyond the supply chain onto the store or warehouse floor, field services, and even customer service. - Trust machine learning. Machine learning will self-optimize each step of the supply chain using the data and information generated from AI and predictive analytics. Beyond a massive increase in the scope and scale of data management, machine learning allows for novel features like visual pattern recognition and contextual intelligence that provide businesses with powerful new analytical tools. In turn, companies can use this advancement in data insight to help identify new efficiencies, optimizations, and ultimately cut costs and increase revenue generation.

- Automate. Automation is a vital component of enacting a truly intelligent supply chain as it is key to increasing overall speed – the first and most important step in improving the efficiency of the supply chain. This ensures that manufacturers receive the timely delivery of components and can stay on track to ship their own products. Retailers can better maintain inventory levels to ensure customer satisfaction for both in-store and online shoppers looking for BOPIS/BOPAC. Beyond optimizing fulfillment, automation can greatly improve the efficiency of other integral parts of the supply chain – such as sourcing, distribution, and procurement – for manufacturers, suppliers, and retail stores.

How to Leverage the Intelligent Supply Chain

- Automate the warehouse and distribution center. Retailers and manufacturers should look into automated hardware solutions such as autonomous mobile robots (AMRs), picker robots, cobots, and automated conveyor systems. Future automation can even extend to automated delivery drivers that would allow for effortless transport across the “last mile” of delivery. Far from supplanting human positions, these autonomous solutions can be a supplement for employees, enabling them to be more efficient and accurate in their tasks, allowing them to focus on higher-level responsibilities.

- Invest in digital solutions. Updates to your digital resources, both hardware and software, will provide greater visibility into all areas of your supply chain. Hardware such as remote sensors and IoT devices can physically tag items in transit to update you on their location, or let you know if they’re just sitting in a warehouse. Microsoft Dynamics 365 application software can provide enhanced forecasting and planning as well as order management solutions to keep things more organized. Advanced solutions, such as machine learning AI analytics, can provide predictive logistics updates about everything from potential global disruptions to which delivery route will have the least amount of traffic.

- Optimize fulfillment. Insights about the efficiencies of your supply chain can help point you toward the best way in realizing fulfillment. Perhaps as a start-up business, you are utilizing Third-Party Logistics (3PL) but now are at a point where the data says it makes more sense to invest in your own distribution center (DC) or warehouse. Conversely, perhaps insights reveal that your DCs are costing more than they’re worth, and it could be worthwhile to explore how to restructure your resources or even consider partnering with a 3PL company. Intelligent order management solutions, like Hitachi Order Management Solution, can provide your customers with convenient features like self-service portals while streamlining order processing to keep everything agile and convenient.

- Breakdown silos. Both information and products can be trapped within their own, separate silos. Digital technology can expand the scope of what falls within the supply chain for a “bigger picture” of available data and the status of products. Managing an extended supply chain network requires a rethinking of processes and the employment of AI technologies. Breaking down silos enables greater collaboration between internal teams and greater efficiency between industries, providing benefits for both manufacturers and retailers.

- Inform your strategy. Knowledge is power, and the insight provided by intelligent supply chains can help businesses understand every point of their supply chain. This can enable a better understanding of specific pain points and overhead, from delays and regional regulations to freight and shipping costs. In turn, this can inform more accurate forecasts, help foster relationships with your partners, and – most importantly – maximize your profit margins.

To take advantage of the intelligent supply chain, businesses should strike a balance between implementing intelligent solutions and training supply chain professionals. As powerful as this technology is, optimal efficiency can only be achieved following company-wide buy-in and successful adoption by all teams – from top to bottom.

Why Hitachi Solutions

The foundation of an intelligent supply chain system is a robust digital solution that touches every point of CPG, manufacturing, and retail operations. Successful implementation of an intelligent supply chain requires a holistic approach to technology, system design, operations, and personnel. Here are some considerations that will effectively guide your digital transformation:

| Supply Chain Requirement | Realized Benefits | Technology Solutions |

|---|---|---|

| Need a structured approach to incorporate and analyze all relevant supply chain data. | Data-driven decision powered by machine learning. Enhanced reporting and predictive analytics. Actionable business insights delivered in real-time. | Information & Insights

|

| Need a modern technology system that’s scalable, efficient, and secure. | Scalable to handle enterprise-wide “big data” assets. The faster performance allows greater agility and flexibility. Cloud-native security provides next-gen data protection. | Modern Infrastructure

|

| Need to eliminate data silos and connect all relevant departments and teams into a single environment. | Streamline and automate business operations. Connect and manage operations in a unified environment. Improved visibility into operations and personnel. | Unified Operations

|

| Need to streamline user adoption of the new system to minimize downtime and maximize confidence and buy-in. | Effective tech adoption reduces risks and increases ROI. Implement full process change, not just new tech. Scope projects and train employees to successfully meet objectives. | Enhanced Capabilities

|

At Hitachi Solutions, we have been building custom solutions for businesses of all types and sizes who are looking to transform their operations and maximize efficiencies. To start your digital transformation, download our white paper on the Intelligent Supply Chain and contact our team today.