Artificial Intelligence (AI) holds the potential to revolutionize the manufacturing industry by ushering in an era of unprecedented efficiency, cost reduction, and operational agility. As the world continues to evolve, envisioning a future where interconnected machines operate seamlessly under the guidance of AI becomes increasingly plausible. From executive decision-making to shop floor operations, AI promises transformative change across every area of manufacturing.

A Current Snapshot of AI in Manufacturing

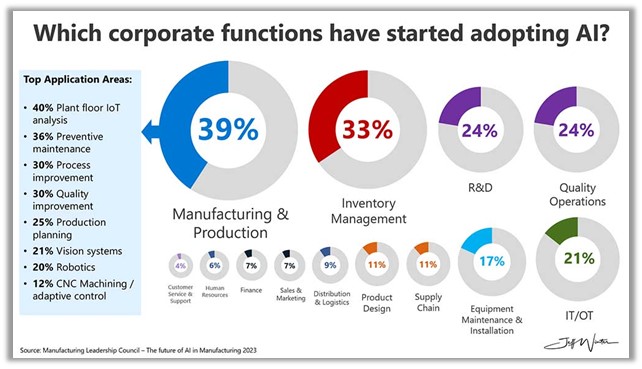

With AI, the possibilities seem endless. But first, I wanted to take a quick look at the present AI landscape. Because today, AI adoption is increasing and some of the tangible benefits — such as plant floor IIoT analysis, preventive maintenance, and process and quality improvements — are being seen in many areas.

For example, insights from the Manufacturing Leadership Council’s 2023 research shows:

- Approximately 57% of manufacturers are investigating AI applications and striving to identify areas where its implementation could yield the greatest advantages

- 29% of manufacturers have successfully incorporated AI into their strategic outlook and 28% haveproactively embedded it into their operations

- 96% of manufacturers are eager to boost their AI-related investments

And studies like McKinsey’s 2023 Global Survey further validate these benefits, revealing a majority of manufacturers employing AI witness decreased operational costs and increased revenues. This substantiates AI’s potential to drive significant improvements in manufacturing efficiency and profitability. The study found:

- 55% of manufacturers employing AI witnessed decreased operational costs

- 66% of manufacturers saw a rise in their revenues, with 16% reporting more than 10% increases

- In cost and revenue, manufacturing as a function had higher overall numbers than all 8 other business functions evaluated

Impressive statistics like these substantiates AI’s potential to drive significant improvements in manufacturing efficiency and profitability. The gains are undeniable, which bodes well for an extremely bright future.

Check Out AI in Action

Statistics and forecasts are great, but AI sightings in the real world are even better.

Take Microsoft for example. Their journey to optimize hardware manufacturing processes in China and the U.S. saw a dramatic shift with the adoption of AI. Eager to enhance speed, accuracy, and efficiency, the team implemented a three-pronged AI strategy: connection, prediction, and cognition.

They created dashboards to ensure consistent real-time data views for all while fostering better decision making and boosting operational agility. This contributed to significant financial savings. And the transformation was more than just technical, it was also cultural — something that was imperative for successful AI integration and adoption. They emphasized trust building, role modeling by executives, and constant reinforcement. And the results were impressive:

- They’ve successfully managed a 95% commitment to orders within a two-day timeframe

- Operational errors were drastically minimized, leading to $50M in annual savings

- Process optimization contributed to an additional $10M in savings

- Their ability to forecast demand improved by an impressive 15%

And another example is Nissan. They operate an AI preventive-maintenance platform to generate remaining useful-life forecasting on 7,500 assets. From AI, Nissan claims an unplanned downtime reduction of 50 percent and a payback period of less than three months!

Watch Out for Potholes on the Road to AI

AI presents a future where machines can learn, adapt, and optimize operations. It’s exciting! But the path to AI integration is littered with challenges, and the effectiveness of AI is dependent on several factors including identifying and prioritizing the right use cases and having a solid strategy and plan.

It also helps to avoid costly and time-consuming missteps many manufacturers have made as they navigate the new world of AI. Some of the most common things to watch out for include:

- Jumping the gun — Organizations tend to be so captivated by the charm of AI that they lose track of their goals. They invest heavily in technology, only to realize they should have defined objectives and outcomes first. AI, despite its myriad uses, can easily divert you to unrelated capabilities, minimizing value and ROI and causing initiatives to stall.

- Misunderstanding AI capabilities — It’s important to keep expectations realistic. AI is not a cure for everything. Although it can process enormous quantities of data at lightning speed, it struggles in areas requiring human intuition. Complex decision-making scenarios, unpredictable situations, and nuanced analyses are still best managed with human expertise.

- Disregarding ethics and privacy — From biases in algorithms that can perpetuate discrimination to issues of transparency and accountability, AI presents a new array of ethical challenges. There are dilemmas of creativity versus ownership; the potential for misinformation; and a range of data concerns such as privacy, security, and surveillance. You have to proceed with caution because as technology evolves and social sentiment changes, new ethical considerations will continue to emerge.

- Overlooking a data strategy — Data is at the heart of digital transformation and AI. According to the McKinsey Global Institute, the manufacturing industry collects and stores more data than any other industry, nearly double the next highest industry. But it is not sufficient to just have data. Quality, diversity, and relevance of this data are key. Without a solid data strategy that ensures you have the right data when you need it, even the most sophisticated AI models will be unreliable and underperform.

- Treating AI as a short-term project — Because many companies are so eager to try AI, they only consider it for short-term projects. But this limits its potential. Recognizing AI as a strategy for growth and innovation enterprise-wide is the only way to unleash its transformative capabilities.

Think about these potential roadblocks before implementing AI in your organization. By avoiding them, you can more effectively tap into the true power of AI, unveil new opportunities and outcomes, and unlock even more possibilities.

Your Roadmap for Success

So how do you start? A good first step typically involves introspection — recognizing your company’s existing abilities, potential obstacles, and pinpointing the areas where AI could provide the most significant transformation. This necessitates a combination of top-down leadership dedication and bottom-up skill enhancement.

Also, it’s best to begin small, concentrating on key pilot projects that can offer quick wins while cultivating internal trust. As you gain more experience and expertise, you can broaden AI applications across larger sectors, ultimately transitioning from simple problem-solving to strategic, future-focused solutions.

Having everything in place, including a modern data strategy, to leverage AI to help your organization be more agile, efficient, and profitable can be a challenge for many manufacturers without the in-house experience or resources. That’s why working with an experienced and knowledgeable partner is another great first-move to successfully meet your AI goals.

Explore AI with Hitachi Solutions

Hitachi Solutions is a leader in digital transformation in the manufacturing industry and we are the perfect partner to ensure you are ready, willing, and able to leverage AI. That’s because with Hitachi Solutions on your side, you have end-to-end support — from strategic advisory and leadership skills to valuable data and AI experience to deep technology and solutions expertise.

Together, we can help you unlock the true potential of AI to drive innovation, boost competitiveness, and achieve unprecedented levels of efficiency and productivity. Whether you are kickstarting your AI journey or want to get to the next level, contact us today.