Facts and Strategies You Need to Know for Industry 4.0

No matter your industry, artificial intelligence (AI) is a hot topic. For manufacturers in particular, it is transforming the industry like never before. From process automation to quality control to predictive analytics, AI has become a key area of focus for those looking to improve efficiency, productivity, responsiveness, and agility.

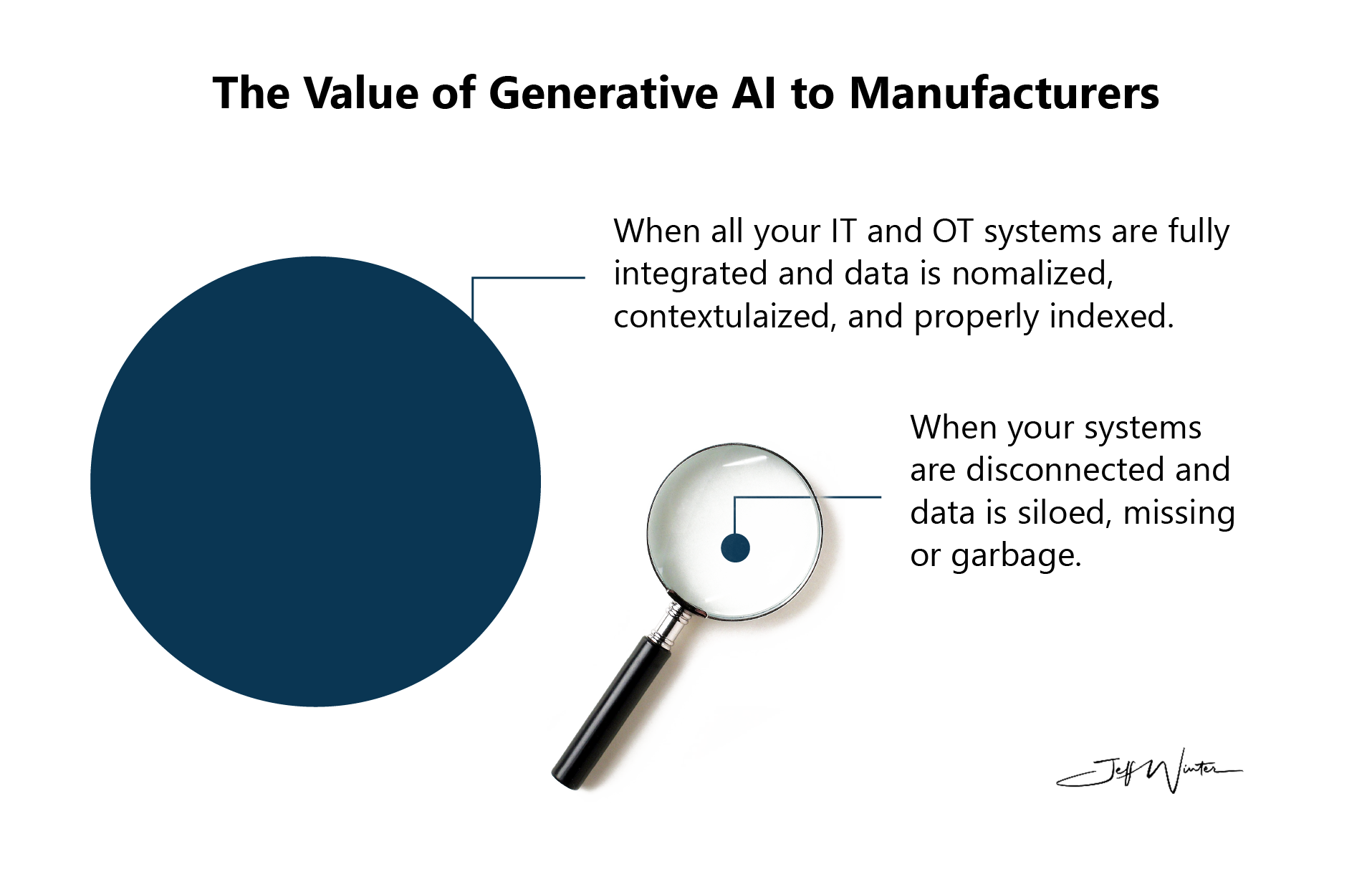

With so much data being produced daily by industrial IoT and smart factories, manufacturers are increasingly turning to AI solutions like generative AI, machine learning, and deep learning neural networks to better analyze data and leverage it to make more informed decisions. And the possibilities are endless — from automated defect detection and flaw classification to more accurate demand forecasting and less material waste to personalized interactions and recommendations, and much more.

So how do you get in on the action and add AI to your manufacturing toolkit?

I recently participated in a podcast, Manufacturing Happy Hour, where I break down the different types of AI, give an update on some of the latest manufacturing AI trends and strategies, identify some common AI use cases for manufacturers, and offer advice on how to best move forward with AI in the age of Industry 4.0.

To help you get started on your AI journey, I wanted to share some of the discussion with you. Check out these helpful highlights:

A Healthy Approach to AI for Manufacturers

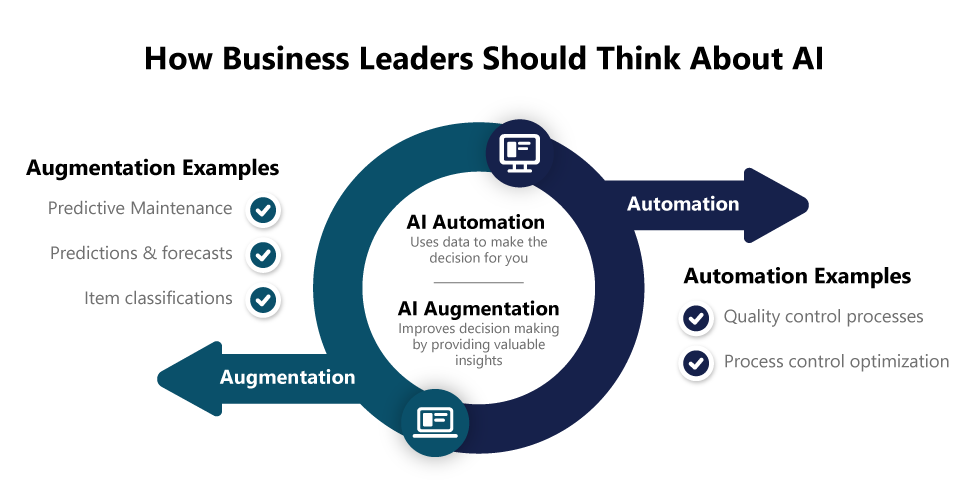

AI can be a valuable tool in the manufacturing industry, offering two primary use cases — augmenting and automating decisions.

Augmentation

AI can augment decision making by providing valuable insights from complex data sets that humans might overlook. For example, AI could be used in predictive maintenance, a process in manufacturing where AI algorithms analyze equipment data to identify patterns that predict potential failures. With this knowledge, maintenance technicians can intervene in a timely manner, thereby reducing downtime and saving costs.

It can also be used to sift through millions of data points to look for patterns or correlations; help with predictions and forecasts, classification and grouping of items; and — with generative AI — help to generate content, images, and even new code. All of these assist a human with their job and their decisions.

Automation

This is where AI does the task for you or makes the decision for you. An example in manufacturing is quality control. Traditional quality control processes might involve manual inspection and classification of products, a task that can be time-consuming and prone to human error. Computer vision using AI can automate this process by analyzing product images, identifying defects, classifying product quality, and even determining the best corrective actions to be taken.

Another example is real-time process control optimization. This includes using reinforcement learning and simulation — when an AI model can make process parameters on-the-fly, reacting to environmental changes — and it will learn from its actions to improve itself over time!

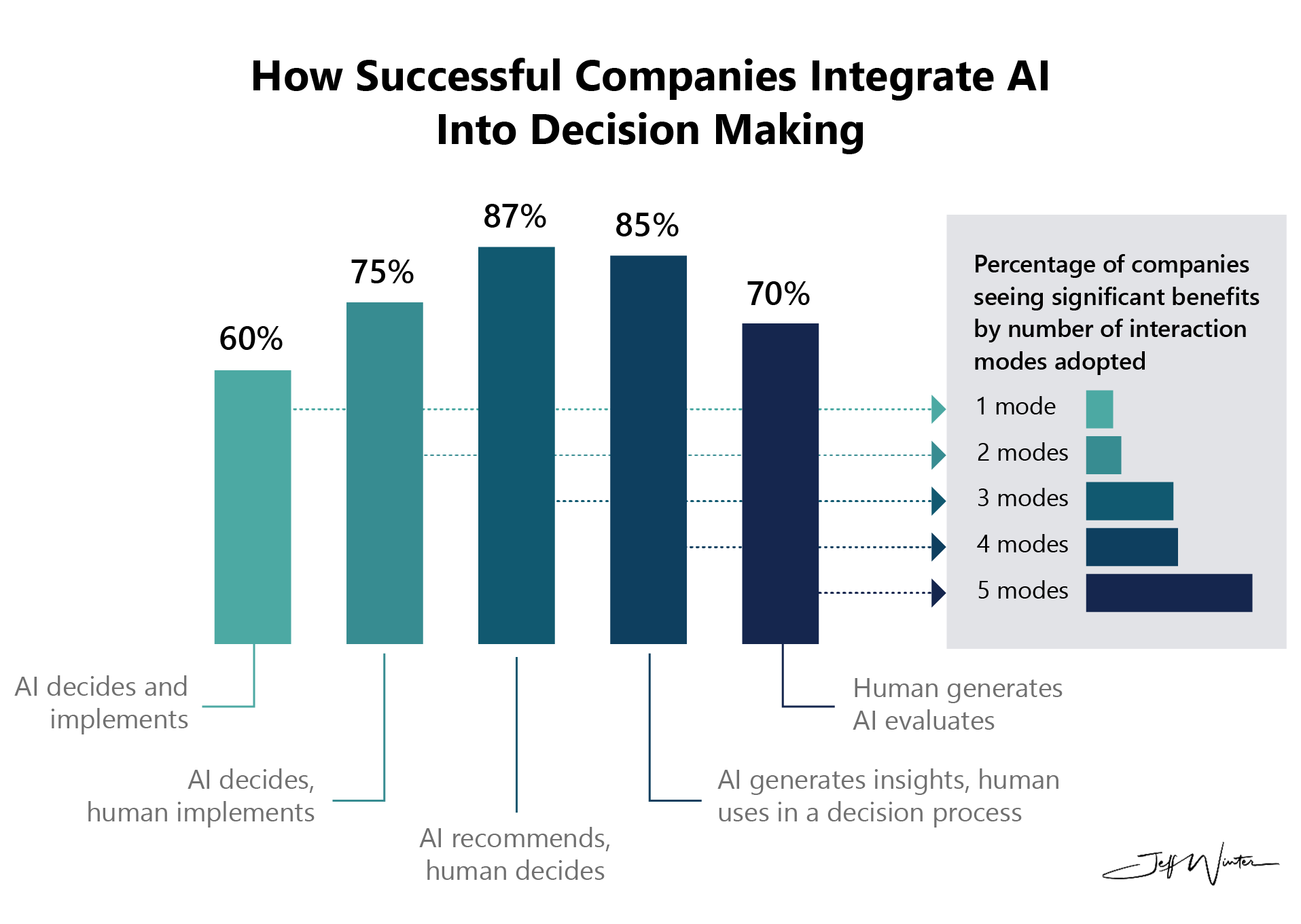

In a study done by MIT and Boston Consulting Group, they identified five progressive modes to that help humans make decisions with AI. The progressive modes start with 1) human generates an answer and AI evaluates, then works up to 2) AI generates insights and human uses in a decision process, then 3) AI recommends an answer and human decides, then 4) AI decides and human implements, and finally 5) AI decides and AI implements.

The companies that saw the greatest financial benefits were the ones who used all five modes, not always aiming for total automation with AI deciding and AI implementing. So, it’s about finding the right places to use AI the right way for your company.

The Impact of AI Policies in the Manufacturing Workplace

Generative AI is still so new that even early adopters are only starting to create policies around it[AS1] . So, there is no track record to validate the effectiveness of these policies yet — it’s just too early to tell.

But, if you expand to the broader AI, not just generative AI or ChatGPT, then you start to see more mature policies in place. For example — companies have policies around privacy and data protection as part of their AI initiatives. This then expands to ethical or responsible AI. In June of 2022, Microsoft publicly released their internal responsible AI standard, and made it available for anyone and everyone to use. It is 27 pages, not super in depth but it is a great start.

AI transparency is another big area companies are focusing on right now — basically being able to clearly document and articulate how AI systems make decisions. Transparency builds trust with users and stakeholders, and also helps to ensure AI is being used responsibly.

The part most companies are scrambling to figure out, though, is ChatGPT. Since ChatGPT is a publicly available and easily accessible application, how do companies police it? And govern it? Because, whatever you put in the public facing ChatGPT prompt is now data that is available to OpenAI. So that begs the question of what data can or should employees load into the public ChatGPT? It’s a tricky question.

AI Use in Manufacturing

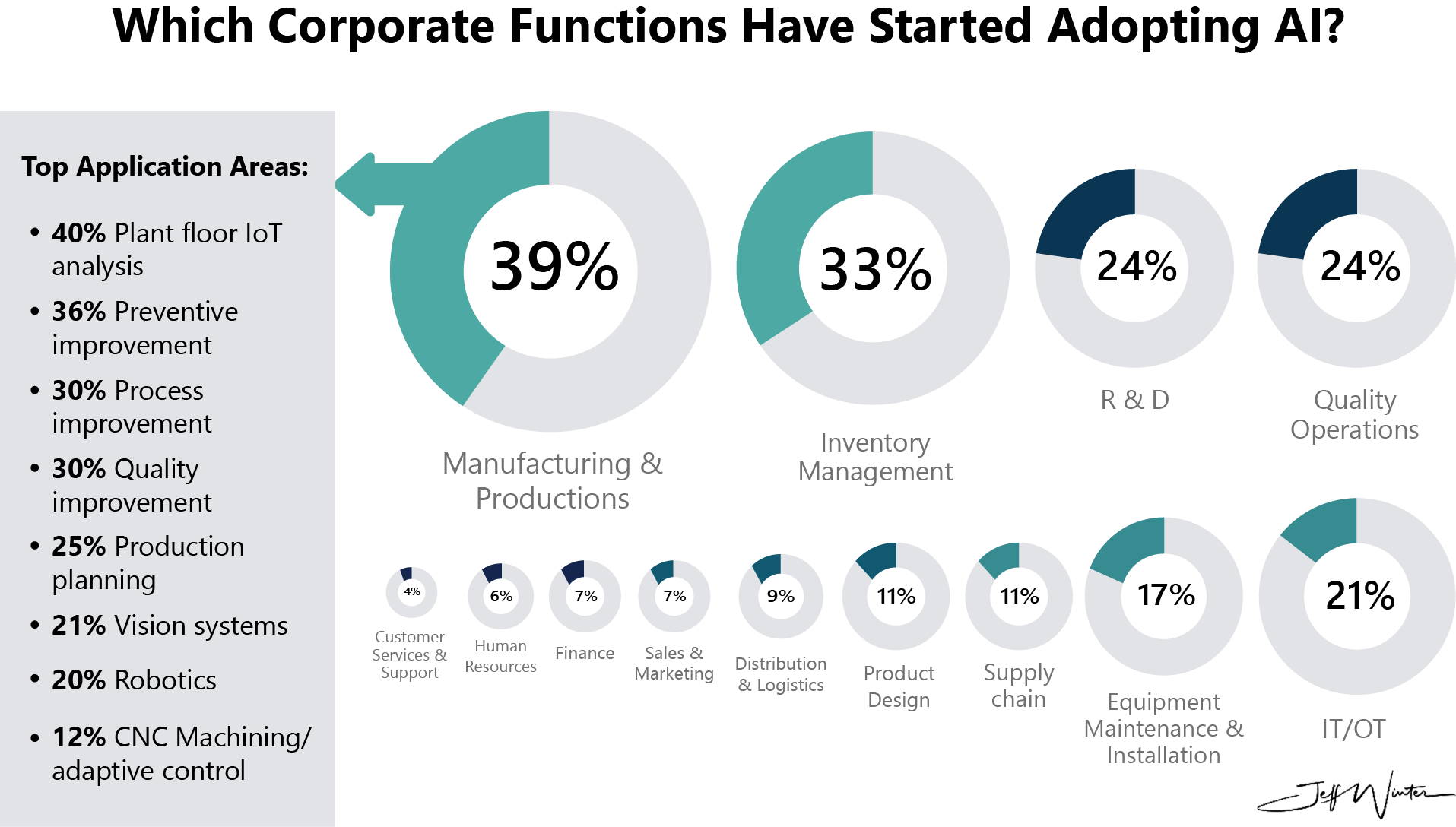

The Manufacturing Leadership Council just released a new report in June of 2023 on how manufacturers are leveraging AI. And there were some interesting statistics in there.

First off, they showed how within the manufacturing industry, the function of manufacturing and production has the highest percentage of adoption at 39 percent. Inventory management came in second, and R&D — surprisingly — came in third and was tied with quality. If you dive deeper into the manufacturing function, shop floor IoT analytics was the top use case and preventative maintenance was second, specifically for AI.

Another interesting observation here is how manufacturers are measuring success of their AI initiatives. Just 22 percent of respondents said they had a specific set of metrics in place to measure AI deployment effectiveness and impact. That leaves 61 percent reporting no metrics are in place and 17 percent reporting they do not even know if metrics exist.

Of those reporting their organization has AI effectiveness metrics in place, 35 percent say they are measuring asset availability, 33 percent are measuring quality of results, and 27 percent are measuring unexpected insights. Cost savings and time savings came in behind those, which is interesting as those should be the easiest to quantify into ROI.

This tells us quite a few companies are rushing into AI without thinking through the details of how they are going to know if it works or not. But what is clear is that there is a huge opportunity here for companies to better demonstrate how AI is making an impact.

Advanced AI Use Case

Actually, one of my favorite case studies about AI in manufacturing is Microsoft. Most people forget, or don’t realize, they actually are a manufacturer and not just a software company. In fact, they have more than 42,000 SKUs at 33 manufacturing facilities and distribution centers.

Microsoft’s manufacturing teams in China and the U.S. integrated AI to enhance their operations. The strategy had three main objectives — Get connected, become predictive, and grow to be cognitive (which means train the system to ideate solutions that enhance human abilities).

The system they developed not only monitored individual machines but also provided an overview of all machines simultaneously. This holistic view allowed for early detection of potential issues, preventing machine failures and production halts. Data was used from inventory as well as sales and even promotions.

Factory workers initially expressed concerns about real-time data being shared with executives, fearing premature reprimands. But with everyone acting on the same data, significant improvements were observed:

- Order commitments improved from 40% within five days to 95% within 48 hours

- A $50 million year-over-year reduction in errors

- Savings of $10 million from waste reduction and process optimization

- 15% more accurate demand forecasts

- A more engaged and informed workforce across all levels

Another great example of AI in action in manufacturing is Nissan. According to IoT Analytics, they run an AI preventative maintenance platform to do remaining useful life forecasting on 7,500 assets. Nissan claims an unplanned downtime reduction of 50 percent and a payback period of less than three months.

An Update on AI and Industry 4.0

There are actually two reports that give some great updates on Industry 4.0 that I wanted to share. One is the IoT Signals by Microsoft and Intel, and the other is the 2023 State of Manufacturing report by Rockwell Automation.

One of the interesting statistics that stands out to me from the Microsoft report was that 86 percent of survey respondents consider OEE to be the most important KPI for measuring a smart factory’s success. Operational improvement tops workforce enablement and sustainability as the leading KPI for measuring the success of their Industry 4.0 strategy.

This study also shows factory KPIs improved by 15.3 percent in the last three years, which is notable by itself. It adds that KPI improvement is expected to be 66 percent over the next three years, which shows an impressive level of ambition. These findings suggest that manufacturers around the world are realizing tangible benefits from their initial use case deployments and are thus willing to boost their investments and efforts to implement a smart factory.

Interestingly, if you compare that to where manufacturers are investing over the next three years, the #1 area is industrial automation-based process control and #2 is condition-based monitoring. I would argue these are Industry 3.0 initiatives, not 4.0. This tells me manufacturers realize they can’t do some of the cool Industry 4.0 things, such as using AI, if they don’t have the basic foundations in place. So, Industry 4.0 related projects are not only accelerating, they are also driving a larger chunk of Industry 3.0 projects.

The Rockwell report takes a slightly different view and doesn’t directly answer the top spending categories over the next three years. However, it does state which ones are planning to increase in investment. Cloud technology/applications/infrastructure came in first at 44 percent and process automation came in second at 42 percent.

If you combine this with the Microsoft report, not only is process automation a huge spend category it’s also increasing in investment!

A caveat is that these reports were done before ChatGPT, which is — hands down — the most disruptive technology change for Industry 4.0 recently.

Some Advice for AI Upskilling and Leadership

For people entering the Industry 4.0 workforce or wanting to update their skills with AI, you have to embrace continuous learning with a growth mindset, spread your wings into new disciplines, focus on cybersecurity, and think like an analyst.

With that in mind, here are my four key pieces of advice I can give to help achieve those things:

- Seek hands-on experience — Theory and knowledge are essential, but practical experience is equally important. Seek opportunities to work on real-world projects or internships that involve Industry 4.0 technologies. Hands-on experience will enhance your problem-solving abilities and allow you to apply your knowledge in a practical setting. There are training programs out there at universities, like the digital foundry at Penn State, which offer a hands-on certificate program in digital manufacturing. There are other groups like SACA (Smart Automation Certification Alliance) that partner with schools and companies to offer hands-on training and certifications.

- Engage in collaborative projects — Embrace teamwork and collaboration, as Industry 4.0 often involves cross-functional projects. Engaging with professionals from diverse backgrounds will help you gain new perspectives, refine your skills, and foster creativity. A good example here is to ask to be included in IT related projects, or any discipline that is far removed from your knowledge base, yet still is technology related.

- Stay on top of industry trends — Follow industry news, tech blogs, and reputable sources to stay informed about the latest advancements in controls, automation, and Industry 4.0. Being up to date with emerging technologies and trends will give you a competitive edge in the job market.

- Build a professional network — Networking is valuable for career growth. Attend industry events, join relevant online communities, and connect with professionals in the field. Networking can lead to job opportunities, collaborations, and valuable mentorship. Join associations and organizations that have similar minded people from your background and who want to learn, grow, and expand into this area. ISA, MESA, and SME are three great examples depending on your background and area of interest.

AI is new and exciting, with enormous potential for manufacturing. For those leading in the era of AI, and who will be hiring an Industry 4.0 workforce, here are some tips that I’ve learn along the way:

- Promote continuous learning — Technologies and best practices are changing so rapidly; you need to make a very concerted effort to stay current. Encourage and support a culture of continuous learning within your organization. Industry 4.0 is a dynamic field, and it’s crucial for engineers to stay up to date with the latest technologies and trends. Offer training opportunities, certifications, and encourage attendance at relevant workshops and conferences.

- Encourage innovation and creativity — Foster a culture of innovation and experimentation. Encourage your engineers to explore new ideas, technologies, and methodologies. Provide them with the freedom to take calculated risks and learn from failures.

- Lead by example — As a manufacturing leader, demonstrate a commitment to learning and staying current with industry trends. Lead by example in embracing new technologies and methodologies. Your enthusiasm and dedication will inspire your team to follow suit. As a company, show you are an innovative, tech forward company. That will help attract the best and brightest talent and keep them there as well.

Ready to Explore More?

If you’d like to learn more about how to unlock the potential of AI in your organization, Hitachi Solutions can help you develop a roadmap for how to meet company goals and priorities, and deliver real business value, with generative AI tools. Or, if you would like to dive deeper into Hitachi Solutions’ AI and manufacturing strategies, contact us today.