Technology is advancing at an unprecedented pace, driving the need for innovation across all industries. But with manufacturing in particular, leaders are grappling with questions about where and what to invest, how to best stay ahead of the technology curve, and how to innovate without overwhelming their organizations.

In a recent podcast, The Manufacturing Executive, I tackle these modern day manufacturing challenges head-on. In this insightful conversation, I shed light on why innovation holds unparalleled importance in manufacturing today, dispel common misconceptions, highlight the changing dynamics of technology adoption, and underscore the significance of formalizing innovation for businesses striving to stay relevant and thrive in this era of rapid change.

Here are some of the highlights from the podcast I thought would be helpful to share. Read on to learn more about the power of innovation and why it matters right now:

A Brief Look at Innovation

Innovation is the practical implementation of ideas that result in the introduction of new goods and services or improvements in the way goods and services are offered. With that in mind, manufacturing innovation is emerging from unexpected places and can support both top line and bottom-line improvement. Those who are digitally transforming are finding newer and more ways to innovate.

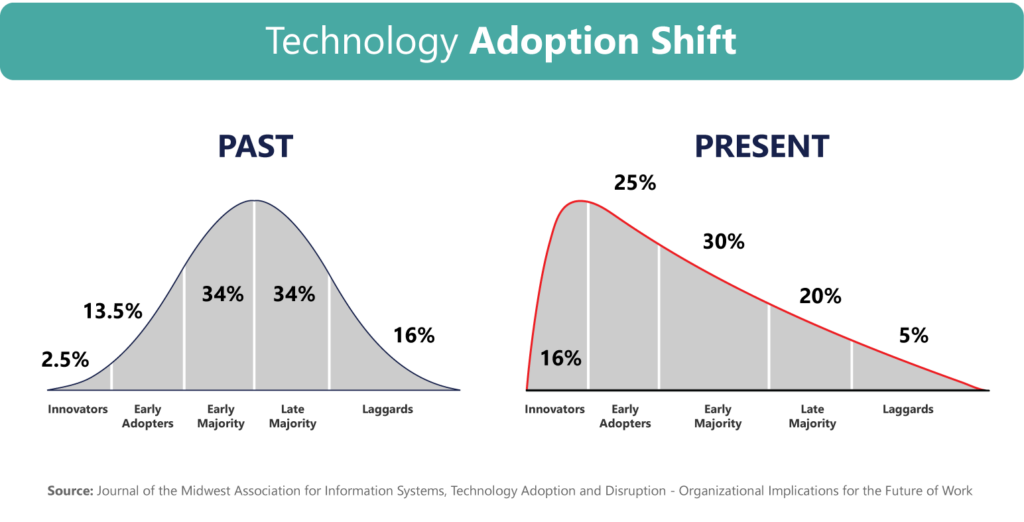

From a history point of view, you may be familiar with the Technology Adoption Curve (most notably attributed to Everette Rogers). It is a sociological model that describes the adoption or acceptance of a new product or innovation based on characteristics of defined adopter groups. It explains how individuals, managers, and even organizations behave in implementing new and innovative technologies. According to this model, adoption has traditionally taken on a normal distribution shape, with a majority of people falling evenly between the Early Majority and Late Majority adoption phases. Very few were Innovators.

In 2020, there was a paper in the Journal of the Midwest Association for Information Systems called Technology Adoption and Disruption. It says the adoption curve is starting to take on a more positive skew, shifting people more heavily into the earlier phases of adoption. Innovators and Early Adopters are no longer the fringe, they are becoming the norm. And the implications of this will be pretty impactful. We will see faster market penetration, increased demand for innovation, greater risk tolerance of people willing to try new things, and potentially even a bit more volatility in the market.

So, what’s driving this shift? In my opinion, there are two things:

- The sheer volume of data generated today is staggering, offering a wealth of opportunities for creative solutions. According to Statista, we are estimated to generate 120 zettabytes worth of data this year. A zettabyte is a one followed by 21 zeros, or a trillion gigabytes.

- The speed of technological progress is unparalleled, with innovations like ChatGPT rapidly gaining widespread adoption. It only took two months for ChatGPT to hit 100 million users after its launch. We’ve never had anything close to that in terms of adoption before.

One example of this happening in real life is the increase in the number of Chief Innovation Officers (CINOs). The role didn’t exist 20 years ago and today, according to Forbes, roughly 30 percent of Fortune 500 companies now have that role in place. And according to LinkedIn, there are over 13,000 people with the title of Chief Innovation Officer and over 270,000 people with a title that includes “innovation” in it.

For those companies still without an official innovation role, the Chief Information Officer (CIO) has this responsibility 40 percent of the time, according to IDC. This means the CIO is no longer just focused on just managing information, data, and knowledge systems. Now, the role includes driving innovation by accelerating all the other functions of the company through integrated technologies.

What is clear is that business leaders, and especially CIOs, now see that technological progress and market conditions are changing so fast that failure to react quickly can be catastrophic. All companies need to innovate more and faster than they ever have before.

Common Innovation Misconceptions

Despite technological advancements accelerating and market conditions evolving at an unprecedented pace, there are still several misconceptions surrounding innovation we need to be aware of and debunk:

- Innovation is NOT the same thing as invention. Invention and innovation, while closely linked, are different concepts. Invention refers to the creation of something completely new and previously unseen — a novel idea, method, or product that comes into existence for the first time. Innovation, however, is a broader concept that encompasses not only the creation of new ideas or products, but also the enhancement, modification, or new application of existing ones. This means that all inventions are innovations, but not all innovations are inventions.

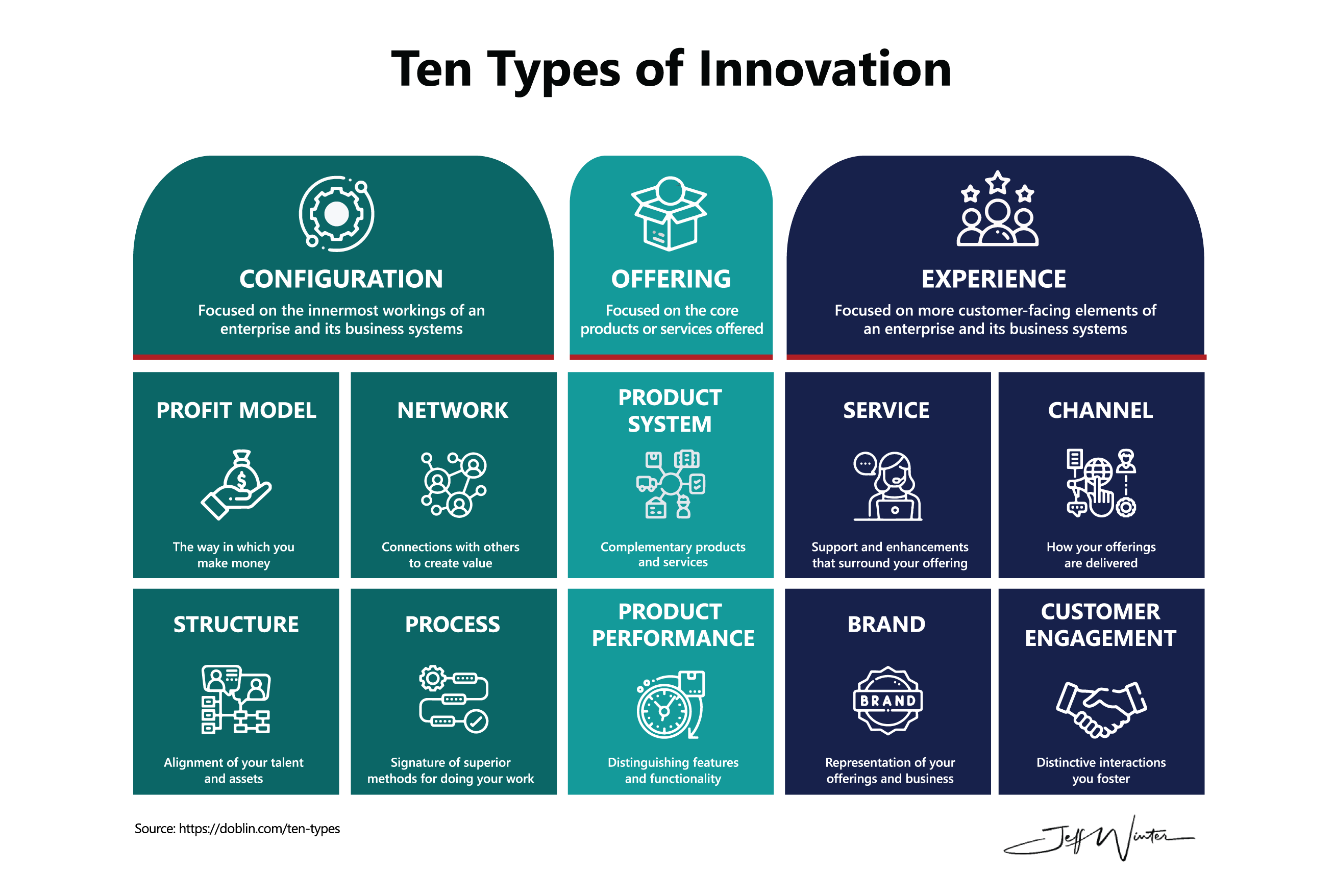

- Innovation is NOT always about technology. While technology often plays a key role, innovation isn’t limited to it. A good illustration of this is Doblin’s Ten Types Framework. It has 10 areas of innovation that are structured into three categories — configuration, offering, and experience. Most big breakthroughs end up being a combination of several types of innovation all coming together.

- Innovation doesn’t happen in “eureka” moments. Very rarely is it a sudden flash of genius. In reality, innovation is a long, iterative process that involves experimentation, failure, learning, and refining.

- You have to be creative to be innovative. Innovation is not solely the domain of “creative types.” It’s a discipline that can be learned and practiced by anyone regardless of their role or background. Often, the best innovations come from diverse teams with different perspectives.

Formalizing Innovation for Manufacturing — What That Means and Why

Formalizing innovation helps align creative efforts with strategic goals, creating a systematic process for ideation and execution. It ensures resources are allocated and processes are established to nurture, test, and implement new ideas.

Without a formal approach, innovation will be sporadic and disorganized, with valuable ideas overlooked, efforts duplicated, or resources wasted. It can lead to a lack of focus and direction, potentially stalling progress and hampering the company’s ability to stay competitive, adapt to change, and drive growth.

Here are the major steps manufacturers might take to achieve innovation formalization:

- Create an innovation strategy — This includes aligning the innovation efforts with the company’s overall strategic objectives and determining what type of innovation the company will focus on (product, process, business model, etc.) and what goals and metrics will measure success.

- Establish an innovation leader with a team/committee — Depending on the size of your organization this may be a dedicated role and team, or it may be a part-time gig for several people. But there needs to be people responsible for leading, managing, and tracking innovation. At Hitachi Solutions, we have a whole innovation team with over 50 people dedicated to it in North America.

- Cultivate an innovative culture — Creating an environment where employees are encouraged to think creatively, take risks, and challenge the status quo is a must. This can include fostering open communication, promoting collaboration, recognizing and rewarding innovative ideas, and accepting failure as part of the learning process. Unfortunately, this is by far the hardest step. It requires huge endorsement by the leadership, and having management at all levels integrate this into everyday workflows.

- Provide resources and tools — It is important to allocate resources (time, money, personnel) to support innovation. This may involve creating innovation labs or spaces, investing in research and development, or providing training and tools to help employees think creatively and develop new ideas.

- Implement an idea management system — This includes developing a system for collecting, evaluating, and implementing new ideas. It could be as simple as a suggestion box, or as complex as a digital platform that enables employees to submit, vote on, and collaborate on ideas.

Manufacturers Formalizing Innovation the Right Way

Process manufacturing

P&G is a great example of formalizing innovation done right. In 2001, they launched their “connect and develop” initiative as a strategic pillar of their innovation program. It is an open innovation strategy where P&G collaborates with external partners — individuals, small businesses, and research institutions — to co-develop new products. This approach has led to a significant increase in the number of new product innovations.

By 2014, P&G’s CIO at the time said the shift from traditional in-house R&D to leveraging external resources increased their R&D productivity by 60 percent and halved the cost of innovation. And they created popular products like the Swiffer Duster and Glad Forceflex trash bags. While this example isn’t new, it shows the power of the process.

Product Manufacturing

I really like the Celli Group example. Celli Group is a global company based in Italy that manufactures and services equipment for dispensing soft drinks, water, and beer. They have more than 400 employees in six production facilities. They are implementing an IoT strategy that connects them to their end customer and enables new service delivery and revenue models.

Celli implemented a model-based system with PLM and IoT as the foundation for this transformation and included a novel “smart warranty” program that is unique in their industry. Their warranty coverage is based on performance against specification rather than time in service. So, the harder you run your equipment, the shorter the warranty and the less you run it, the longer the warranty.

Talk about innovation! And on top of that, by leveraging the data from their IoT connected product, they were able to improve profitability by significantly differentiating its tap and brewery offerings, resulting in:

- 14% greater sell-through via enhanced sales and inventory management

- Reduced equipment failures by 13%

- Improved product quality by 27% by monitoring temperature, shelf life, and sanitation cycles

- Reduced service costs by 10% through better predictive maintenance

Key to this is having the PLM and IoT parts together through the digital thread, which extended all the way out to their customer.

Manufacturing Innovation and Generative AI

How does this approach help manufacturers adapt to disruptive technology like generative AI? In the context of ChatGPT, a company with a formalized innovation process would definitely identify its potential early on, quickly prototype ways to integrate it into their operations or offerings, quickly evaluate the benefits and risks, and then systematically roll it out across the organization.

Employees would be encouraged to test it out (with a governance policy in place) to see where and how they can incorporate it into the company to either help their jobs or enhance customer experience. The sky is the limit with trends like generative AI, you just have to understand how it works, what it is good at, and what it isn’t. The best way to figure that out quickly is to have an innovative culture with an innovation management process in place.

Let’s Innovate Together!

As the manufacturing industry enters this new era marked by technological disruption, embracing innovation has become an imperative. By adapting to changing technology adoption dynamics and formalizing innovation processes, manufacturing leaders can navigate this transformative period with confidence, staying relevant and competitive and driving growth in a rapidly evolving world.

As I mentioned, Hitachi Solutions has a dedicated innovation practice with 50+ team members in North America. They are on-hand to advise, conduct workshops, or just chat about your innovation and modernization initiatives.

Contact us today, we are here to help!