What is production?

Production is the process of creating goods and services, encompassing the entire journey from raw materials to finished products. In manufacturing, production specifically refers to the systematic, large-scale conversion of raw materials into finished goods through the use of machinery, labor, and technology.

Production, as the core of every manufacturing business, is undergoing a significant transformation fueled by digital technologies such as automation, AI and ML, IoT, and more. These innovations are creating smarter manufacturing factories that communicate and collaborate in real-time. Industry 4.0 is often the term given to this transformation specific to manufacturing. And the impact is greatly improving efficiency, productivity, agility, quality, delivery, and profitability.

As a guest on the Peggy Smedley Show a few months ago, we talked about this exact topic. We had a great chat discussing the state of manufacturing production, the biggest challenges and constraints many manufacturers are facing, as well as how AI is affecting the industry. Below are some of the top takeaways from the podcast!

A Brief Industry Update

People are always asking about the state of production today. The answer is to measure it against the vision of Industry 4.0 — which is about leveraging disruptive technologies to completely change the way companies operate, the way employees work, and the way you provide value to customers.

And it all boils down to the ability to capture and harness the power of data to help make better decisions, faster. This involves integrating all your data sources together to have better visibility and control, using analytics to gain totally new insights and predictions, and even turning this data into digital services to generate new revenue streams.

The best way to evaluate companies against this capability is to use a vendor neutral industry assessment to evaluate digital maturity holistically. One assessment is the Smart Industry Readiness Index, or SIRI for short. It was developed in 2017 by the Singapore Economic Development Board and after its partnership with the World Economic Forum in 2020 to form the Global SIRI initiative has since gained popularity around the world. SIRI evaluates a company’s performance across three areas (building blocks) — process, technology, and organization — and 16 supporting dimensions. It uses a 0-to-5 scale where 0 means nothing digital or automated is in place and 5 is fully optimized and autonomous systems leveraging AI and other advanced technologies.

So far, the industry average maturity is only around 1.5. That’s pretty low. Even the top 10 percent highest average score on just one dimension — shop floor connectivity — was still barely above a 3.

Out of 16 different smart manufacturing use cases globally, on average only 2 were considered fully rolled out and 4 were partially rolled out.

IoT Analytics, 2022 Industry 4.0 Adoption Report

In addition, the World Economic Forum (WEF) started its Global Lighthouse Network in 2018 to identify the manufacturing facilities who were implementing Industry 4.0. As of December of 2023, they have only identified 153 factories. To give a frame of reference, there are around 300,000 factories in the U.S. alone.

So, the Industry 4.0 transformation is just getting started.

Top 3 Challenges for Production

In the rapidly changing landscape of modern manufacturing, production faces three critical challenges that demand immediate attention: labor shortages, evolving customer expectations, and cybersecurity threats. These factors not only disrupt traditional workflows but also require innovative strategies to ensure efficiency, security, and customer satisfaction in an increasingly competitive market.

Labor Shortages

According to research done by Deloitte and the Manufacturing Institute, the manufacturing skills gap in the U.S. could result in a net need for as many as 3.8 million jobs by 2033. They also note that without significant changes, 1.9 million of these jobs could remain unfilled. And 65 percent of survey respondents said attracting and retaining talent is their primary business challenge.

In its latest Annual State of Smart Manufacturing Report, Rockwell Automation showed the top internal challenge for manufacturers is attracting employees with desired skills, and the fourth highest external obstacle is a shortage of skilled workers. And the impacts are huge. According to WEF in their 2023 Future of Jobs Report, three out of 10 manufacturing companies in Europe reported production constraints in the second quarter of 2022 due to a lack of workers.

It’s a major concern, and companies are looking to technology — such as automation and AI — to help fill that gap.

Evolving Consumer Expectations

Consumer buying habits are changing fast! This includes sentiments and interests for buyers, mechanisms for how people shop, and how they buy. And the changes all point to a new digital consumer.

For example, the industry is seeing more demand for transparency around the products being purchased and the company itself. People want to know what products are made of and how they will be disposed of. With food, they want traceability throughout the entire supply chain.

People also want to know more about the companies themselves. Sustainability, being environmentally friendly, and acting ethically have become decision criteria in the purchasing process. IBM conducted a study that found 73 percent of consumers consider sustainability and environmental responsibility to be at least moderately important in a brand value. And if you are wondering how that really impacts purchase, you’ll want to take note out this Harvard School of Business report that found sustainable products have 5.6X higher average growth compared to those that aren’t marketed as sustainable. So, yeah, it matters.

73% of customers prefer to do business with brands that personalize their shopping experience.

Pitney Bowes

Today’s digital consumers also desire a much more personalized shopping experience. According to Pitney Bowes, 73 percent of customers prefer to do business with brands that personalize their shopping experience. And consumers are also demanding a faster response to queries and expect faster delivery, right to the doorstep.

And those are just a few of the trends! But honestly, no matter the trend, without digitally transforming your production capabilities, it will be hard to keep pace.

Cybersecurity Threats

As the manufacturing and production environments incorporate technologies like IoT, AI, and big data analytics, ransomware attacks, theft of intellectual property, and disruptions to industrial control systems are on the rise. Advanced interconnectivity in manufacturing enhances data sharing but demands robust cybersecurity measures against unauthorized access and data breaches.

In 2022, Statista showed manufacturers held the highest share of cyberattacks compared to other critical industries worldwide — almost 25 percent of total cyberattacks recorded.

Manufacturing had the highest ransomware incident and recovery engagements by industry at 28%.

Microsoft 2023 Digital Defense Report

To maintain success in an ever-evolving manufacturing landscape, you need an end-to-end security strategy that will keep your production environment safe today as well as tomorrow.

AI’s Affect on Production

Of course, you can’t read an article about manufacturing today that doesn’t mention AI! AI is extremely versatile in its application and can impact every part of a company, from the shop floor up to the C-suite.

If we just focus on production, advanced AI technologies can help improve productivity by over 20 percent (per a 2023 Boston Consulting Group study). Yet, despite 90 percent of companies wanting to integrate AI into their operations, only one-sixth have achieved their AI goals. This is largely due to the lack of foundational prerequisites, organizationally and technologically.

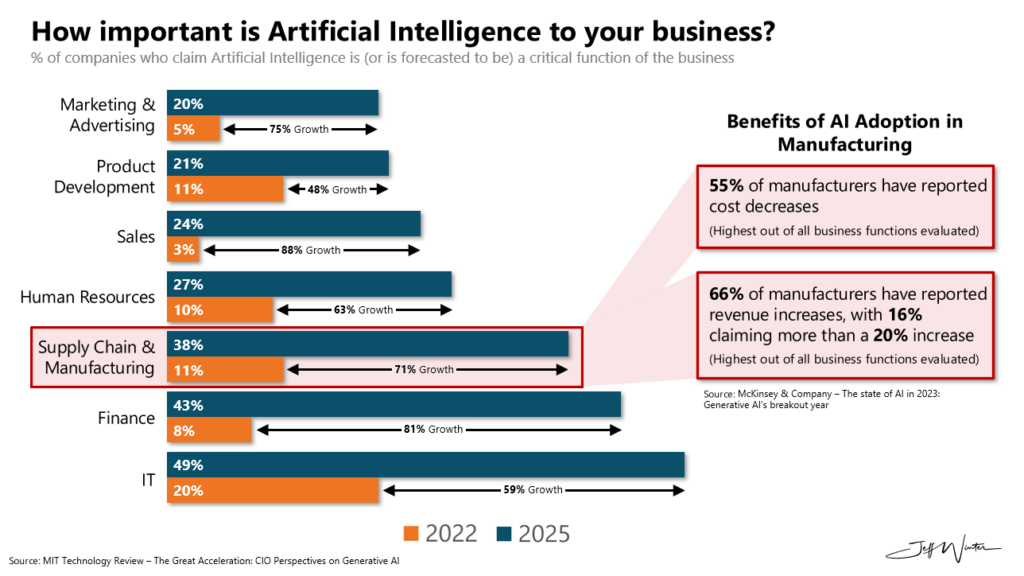

In McKinsey’s State of AI in 2023 report, despite the rise of generative AI, AI adoption remains consistent. Notably, manufacturing has witnessed the highest level — in both revenue increases and cost reductions.

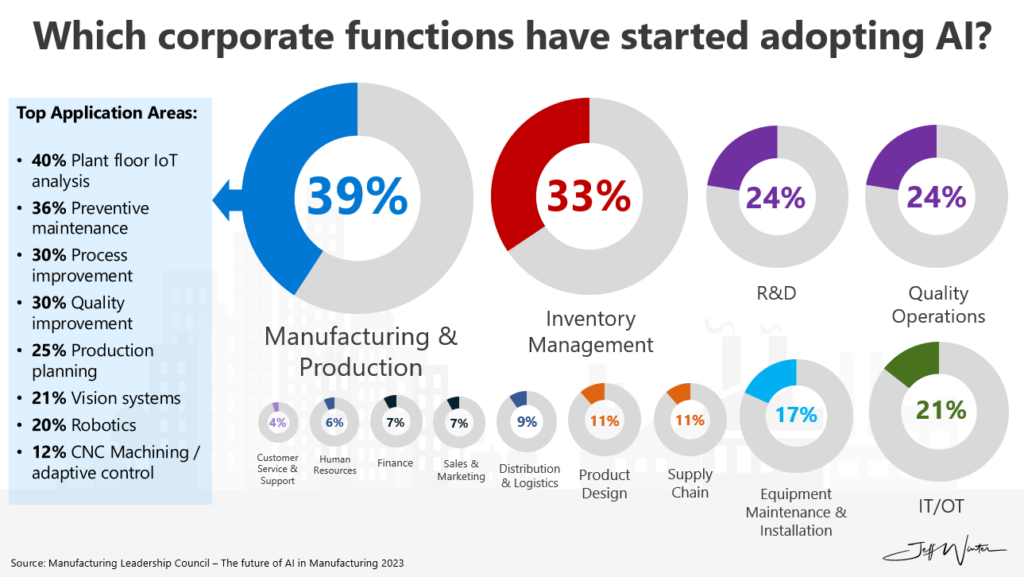

According to Manufacturing Leadership Council’s 2023 The Future of Industrial AI in Manufacturing Report, of all the corporate functions within the manufacturing industry, production takes the top spot for adoption at 39 percent. This is followed by inventory management at 33 percent and R&D at 24 percent. Within that 39 percent for production, plant floor IoT analysis is the top application area. Next is preventative maintenance and then process improvement and quality improvements.

Future Predictions

So what does the future hold? Well, you have heard of Skynet from the Terminator movies, right? Machines controlled by AI taking over the world.

More realistically, we are going to see AI upend and change a lot of things in manufacturing. As we start to learn where to apply the technology we will know where we can automate tasks and where we can augment people to be more effective and efficient. Either way, many jobs, tasks, and functions will change to adapt.

And once we fully analyze and take advantage of the data we are producing and consuming, companies will probably make a whole new round of changes. This will be a continuous process. As we learn more, we pivot. As we learn more again, we pivot again.

But in general, we will see our production processes become more digital, smarter, more autonomous, and more agile. And that is the vision of Industry 4.0. We are living in an exciting time right now!

Let’s Strategize!

Be sure and check out the podcast to hear my full take on the state of production today. And if you would like to learn about how you can start your Industry 4.0 journey and explore AI, automation, ML, or security technology for your company, please reach out.

Hitachi Solutions has been helping manufacturers modernize for 20 years. We have industry-proven expertise, innovative solutions powered by Microsoft technology, and deep technical know-how. Our team is uniquely equipped to help you with your digital transformation strategies and initiatives.