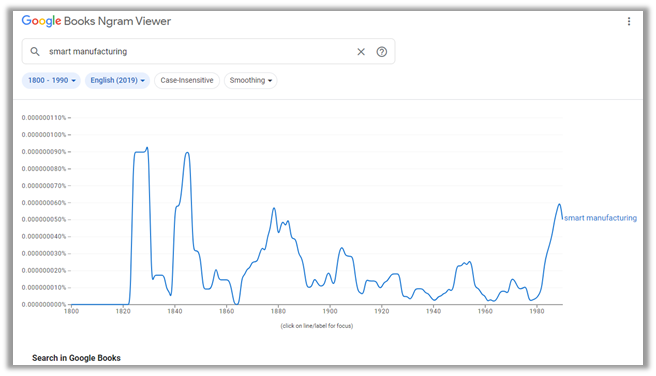

The term “smart manufacturing” has gained significant traction in recent years. But what does it truly mean? To shed more light on this topic, I was asked to provide my insights in an episode of the Manufacturing Happy Hour with Chris Lueckes during the CESMII annual meeting.

At its core, smart manufacturing harnesses the power of technology and enhances manufacturing processes, improves efficiency, and drives innovation. To provide more clarity on this movement and mindset that is taking the industry by storm, I thought I would share some of the highlights from our conversation. Check them out below!

The Essence of Smart Manufacturing Today

The term “smart manufacturing” isn’t new, but dates back centuries under different guises. What sets the current era apart, known as Industry 4.0, is the convergence of cutting-edge technologies — IoT, AI, ML, digital twin, edge computing, and blockchain, to name a few — to completely transform the way companies operate and provide value to customers.

Smart manufacturing today is the integration of these advanced technologies, and data analytics, into manufacturing processes to optimize production efficiency, improve product quality, and enhance operational flexibility. Together, they create interconnected systems that provide real-time data and insights.

This enables capabilities like predictive maintenance, real-time monitoring of equipment, and improved data-driven decision-making, which leads to reduced costs and increased productivity. In essence, smart manufacturing is a result of digital transformation being applied to manufacturing, aiming to create a fully integrated, collaborative system that responds in real time to changing demands and conditions in the factory, supply network, and customer needs.

The Smart Manufacturing Difference

If you were wondering how to compare smart manufacturing to some of the other terms and concepts you’ve been hearing about, here’s a quick rundown:

Connected Factory — A connected factory focuses on interlinking machines, devices, and systems to enable real-time data sharing and automation. While a connected factory is a component of smart manufacturing, the latter goes beyond mere connection, emphasizing predictive analytics, AI-driven decision-making, and holistic process optimization.

Agile Factory — An agile factory prioritizes flexibility and rapid response to market changes. It emphasizes quick production shifts and adaptability. Smart manufacturing encompasses this agility but also incorporates technological advancements for improved efficiency and predictive capabilities.

Smart Manufacturing and Industry 4.0 — Industry 4.0 represents the fourth industrial revolution, characterized by the fusion of digital technologies, automation, data analytics, and interconnectivity. Smart manufacturing is a pivotal aspect of Industry 4.0. While the concept of smart manufacturing has been around for a while, what sets it apart in the Industry 4.0 era is the unprecedented level of interconnectivity, data volume, and intelligent analytics made possible by advancements in IoT, AI, and cloud computing.

“Technology is the vehicle, and a smart manufacturing mindset is the fuel.”

Jeff Winter

Cultivating a Smart Manufacturing Mindset

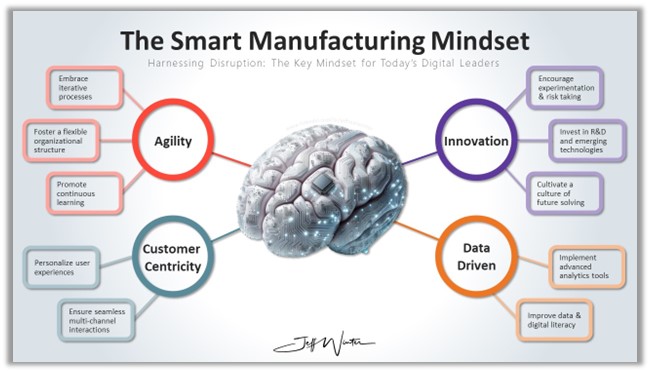

The mindset for smart manufacturing encompasses a set of proactive, forward-thinking principles, attitudes, and values that drive organizational culture and guide decision-making to effectively leverage technology and innovation in manufacturing processes. By embedding this mindset, you can navigate the complexities of the modern manufacturing landscape, drive digital transformation, and achieve sustainable growth and success.

While different organizations have different requirements, a compelling and common framework for establishing a smart manufacturing foundation and mindset focuses on these four key components:

- Agility — Not merely about speed, but the ability to swiftly respond to changes in market conditions, technology, or internal dynamics

- Customer Centricity — Placing the customer at the heart of the manufacturing process, catering to their evolving needs and preferences

- Innovation — Embracing a culture of innovation to leverage technology for continuous improvement and stay ahead of the curve

- Data-driven Decision Making — Harnessing the vast amounts of data generated to inform strategic decisions and drive operational excellence

To adopt a smart manufacturing mindset, you need to undergo a cultural shift that includes embracing technology as a driver for future success. I would also stress the importance of aligning your organizational values with the above principles. By instilling these values and fostering a culture of innovation, you can propel yourself towards success in this new era of smart manufacturing.

Trends Shaping Smart Manufacturing Initiatives

The field of smart manufacturing is continuously evolving, driven by advancements in technology, shifting market dynamics, and changing consumer preferences. Some of the latest trends shaping the landscape of smart manufacturing include:

- The shift from Industry 3.0 to Industry 4.0 involves expanding the focus from production to the entire value chain of organizations

- IoT and AI are significant technologies driving smart manufacturing initiatives

- There’s a trend towards buying off-the-shelf solutions and strategically partnering with an ecosystem of vendors to accelerate implementations and achieve faster ROI

- AI has transformative potential, with companies increasingly adopting it as they recognize it potential to optimize production process and drive efficiency gains

Overall, these trends demonstrate the ongoing transformation of the manufacturing industry toward smarter, more connected, and sustainable operations. By leveraging these trends and advanced technologies, you can drive innovation, improve competitiveness, and unlock new opportunities for growth and success in the digital age.

Ready to Embrace Smart Manufacturing?

One thing that is abundantly clear — smart manufacturing isn’t just a buzzword anymore. It’s a fundamental shift in the way companies should approach production.

Hitachi Solutions is a global leader in providing state-of-the-art digital solutions for the manufacturing industry. With a strong focus on leveraging cutting-edge technologies such as IoT, AI, and predictive analytics, we empower manufacturers to enhance operational efficiency, improve product quality, and optimize costs. With deep industry knowledge and proven expertise, we have helped countless manufacturers achieve digital transformation, delivering tangible business benefits and driving continuous improvement in their manufacturing processes.

To hear more of my insights, or to learn more about Hitachi Solutions’ capabilities, contact us today. We would love to help you embark — or continue — on your smart manufacturing journey.